HOME

Shopping Cart

Sterling Bracelets

Sterling Necklaces

Sterling Brooches

Sterling Buckles

Sterling Earrings

Sterling Rings

Traditional

Archery

Round Combs

Quilt Block Inlay

Turquoise & Silver

Folklore

Sterling Rings

Green Man Ring

Triple Moon Ring

Spider Ring

Custom Rune Ring

Eternal Life Rings

Pewter

Odin Figurine

Brigid's Cross

Porringers

Fairy Tales

Pet Jewelry

Seals & Signets

Special Treasures

Silver Dining Ware

Custom Cut Stones

Leather and Belts

Custom Design

Your Design

Gallery

Show Everything

Gold Work

Friends of the Forge

Measuring Ring Sizes

About Brigid's Forge

Links

Order

Email

All items handmade in the U.S.A.

Exhibiting Members of the

Craftsmen's Guild of Mississippi

You are visitor:

|  |

About Us |

Custom designer jewelry

by Robert and Debra Shinn

|

About Brigid's Forge

The Workshop

The Forge

Visit Us

Local Music

Natchez Trace

Nice Places

Family

Sandcast Ankh - continued

Step 16

Take the flask to the casting box.

Place the upright flask in the casting box,

a wood box filled with sand to contain any spilled metal

and hold used objects that may still be hot.

Firebricks are useful for resting hot objects that do not need to be in the

sand. Two types of crucibles are frequently used for melting the silver: an open dish,

and a covered Burno. For this smaller object, the open dish is preferred.

|

|

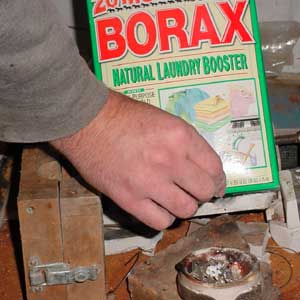

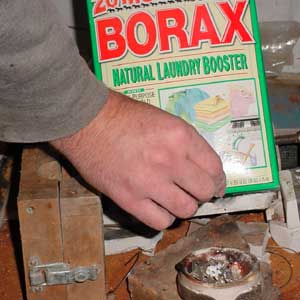

Step 17

Sprinkle borax on the silver.

The silver to be melted is a mix of scrap and casting grain. Sprinkle a pinch

of borax over it in the crucible. Any good laundry grade borax will do.

|

|

Step 18

Boraxed silver.

The sterling silver should appear dusted with the borax.

|

|

Step 19

Heat the metal.

A Prest-O-Lite propane torch is used to melt the silver.

The flame should be close to the metal; the gas should be at about 25 psi.

After thirty seconds, this approximately one ounce of sterling silver

begins to slump.

|

|

Step 20

Melt the metal.

After about two minutes of intense heat the silver becomes a castable liquid.

It will slosh and roll easily as one unit in the crucible. You must continue heating

beyond the first liquid appearance for an extra thirty seconds to have the

metal hot enough to go all the way down the mold.

|

|

Step 21

Pour the metal.

Still holding the flame on the metal, pour the liquid silver down the pour

hole of the flask. Be quick and steady; a break in the stream of metal

entering the flask will likely spoil the piece, leaving it with gaps.

Next, we see what it looks like!

|

|

<< Previous

Next >>

Back to Workshop

Disclaimer: All techniques described are performered by professionals in a professional workshop.

These techniques work well for us; we do not warrant them for anyone else. We cannot be responsible for

anyone's property, profit, or safety. If you wish to make beautiful objects, pictures and

text are no substitute for a good class.

|